Facing the problem of recycling wet and low-pressure materials, our plastic granulators have won the trust of customers with their excellent performance and efficient solutions. Recently, a customer personally brought his wet and low-pressure materials to our factory for a test run, and completed the inspection and receipt of the machine together, which fully reflects the customer’s recognition of our products and services.

Customer Needs and Challenges

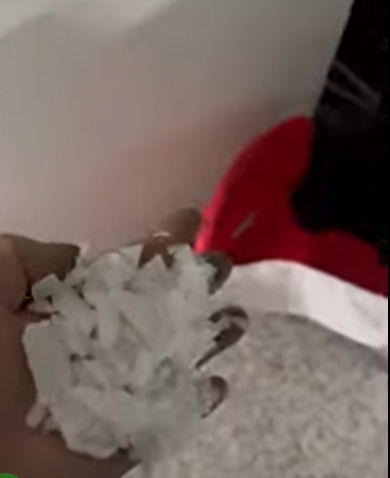

The main demand of the customer is to deal with fragments of wet and low-pressure materials, which have high water content and low density, and are difficult to be dealt with effectively by traditional pelletizing equipment, and are prone to problems such as clogging, low output and high energy consumption. The customer urgently needs a stable, efficient and energy-saving solution for resource recycling.

Our Solution

In response to the customer’s needs and challenges, we recommended a combination of plastic granulator with dryer and automatic feeder. The solution offers the following advantages:

Efficient drying: The dryer can effectively remove moisture from the material and improve the dryness of the material for subsequent granulation.

Stable feeding: The automatic feeder can feed the material into the granulator evenly and stably, avoiding blockage and output fluctuation caused by uneven feeding.

High-efficiency granulation: The plastic granulator adopts advanced screw design and heating system, which can efficiently and stably melt, plasticize and extrude the materials to produce high-quality plastic particles.

Energy saving and environmental protection: the whole set of equipment adopts energy-saving design, reducing energy consumption and environmental pollution.

Labor saving: automatic feeder and automatic control system greatly reduce the need for labor.

Customer’s personal inspection and receipt of goods

In order to ensure customer satisfaction, we invite customers to personally bring materials to the factory to test the machine. During the test run, the customer witnessed the excellent performance and efficient operation of our equipment. After careful inspection, the customer was very satisfied with the performance and granulation effect of our equipment and completed the inspection and receipt on the spot.

Customer Feedback

The customer said that our solution has completely solved the problem of handling humid and low-pressure materials, which not only improves the production efficiency and reduces the energy consumption, but also saves a lot of labor costs. The customer highly evaluated our products and services, and expressed their willingness to establish a long-term cooperative relationship with us.

If you are interested in our plastic granulator – please contact me and leave a message. Thank you.