Are you still troubled by mountains of waste materials and offcuts? Do you still find the costs of processing these materials a headache? Have you realised that what you regard as “rubbish” is actually a “gold mine” waiting to be discovered?

Are you still troubled by mountains of waste materials and offcuts? Do you still find the costs of processing these materials a headache? Have you realised that what you regard as “rubbish” is actually a “gold mine” waiting to be discovered?

In this era of heightened focus on environmental protection and sustainable development, every instance of resource wastage represents a significant loss. For those in the plastics industry, the daily accumulation of waste materials such as HDPE, LDPE, LLDPE, and BOPP from production processes may seem insignificant individually, yet collectively they mount up into a considerable expense. These materials occupy valuable storage space, and their disposal is not only time-consuming and labour-intensive but may also involve compliance with environmental regulations.

Today, however, we present a fresh perspective: a solution that transforms waste into treasure, turning the seemingly worthless into the extraordinary—the low-temperature recycling pelletiser.

Bid farewell to tradition and embrace the low-temperature era

Conventional plastic recycling pelletisers often encounter challenges when processing certain specialised materials. For instance, during high-temperature melting, materials like HDPE and LDPE may degrade, resulting in reduced pellet quality, yellowing, or even odour. This not only diminishes their secondary utilisation value but also limits the application scope of recycled products.

Our low-temperature recycling pelletiser was engineered precisely to address these pain points. Employing advanced low-temperature plasticisation technology, it melts and plasticises waste materials at comparatively lower temperatures. This unique process delivers multiple revolutionary advantages:

Maximises Material Properties Retention: Low-temperature melting effectively prevents molecular structural damage caused by high heat, thereby preserving the original material’s physical properties—such as tensile strength and toughness—to the greatest extent possible, ensuring the quality of recycled pellets.

Preservation of original colour: Prevents yellowing or discolouration caused by high-temperature degradation, resulting in purer, more stable colours for recycled pellets. This broadens their application scope, particularly in products with stringent colour requirements.

Energy efficiency and environmental sustainability: Low-temperature granulation entails reduced energy consumption, lowering production costs while aligning with national energy-saving and emission-reduction initiatives.

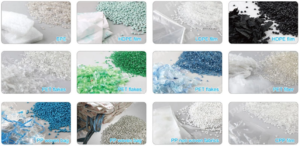

Wider Applicability: Our low-temperature recycling pelletisers effortlessly handle common plastic films like HDPE, LDPE, and LLDPE, as well as composite materials such as BOPP, CPP, and PE/OPP. Even waste containing printing inks or minor impurities is processed efficiently and consistently, transforming it into high-quality recycled pellets.

More Than Just Machinery – Your Money-Making Machine

Choosing our low-temperature recycling pelletiser means acquiring more than just a machine—it’s acquiring a ‘money-making machine’ that transforms waste into profit.

Imagine your daily production offcuts no longer being a burden requiring disposal fees, but instead becoming raw materials directly fed into your production line. Through the low-temperature pelletiser, you can convert this waste into high-quality recycled pellets for direct reuse in your own processes, significantly reducing raw material procurement costs. Alternatively, you may sell these recycled pellets to downstream enterprises, creating new avenues for profit growth.

This represents not merely an economic investment, but a strategic investment in the future. It signifies your contribution to environmental stewardship and your commitment to sustainable development. As environmental regulations tighten and consumer eco-consciousness grows, possessing efficient waste recycling capabilities will become a vital component of your enterprise’s core competitiveness.

Act now to transform waste into treasure

We understand that every investment demands careful consideration. Therefore, we sincerely invite you to explore our low-temperature recycling pelletiser in depth. Our specialist team can tailor the most suitable solution to your specific requirements. We provide detailed performance specifications, cost-benefit analyses, and real-world case studies to help you fully evaluate the value of this investment.

Do not allow your waste materials to lie dormant in corners any longer. Revitalise them to generate fresh value for your enterprise. Now is the optimal moment to initiate this transformation.

Contact us immediately. Together, let us translate environmental principles into tangible economic benefits, truly transforming your waste into valuable resources!