Based on the Chinese article you provided, here is a translation into English.

Dedicated Service, Customer Satisfaction: A Successful Installation Case of a 150 Model Low-Temperature Plastic Recycling Pelletizer

In the rapidly developing plastics industry, equipment updates and upgrades not only represent an increase in production capacity but also reflect a company’s pursuit of quality, environmental protection, and long-term growth. As a professional in the plastic machinery industry, I’ve always believed that customer satisfaction is the greatest motivation. Today, I personally visited a client’s factory and successfully completed the installation and debugging of a 150 model low-temperature plastic recycling pelletizer. I also witnessed the entire production process firsthand. This wasn’t just the successful delivery of a machine; it was the culmination of trust and partnership.

1. On-Site Visit to the Client’s Factory: Seamless Communication

I set out early in the morning, eager to visit the client’s production facility. The client primarily recycles plastic head material for secondary pelletizing. Their old equipment was unable to meet current production needs in terms of energy consumption, stability, and product quality. After multiple discussions and comparisons, the client ultimately chose our 150 model low-temperature recycling pelletizer.

Upon arrival at the factory, we had a detailed discussion to understand their raw materials, production goals, and product applications. After a physical survey of the factory layout, I proposed the best installation plan based on the machine’s features. Throughout the process, the client highly praised our professionalism and sense of responsibility.

2. Smooth Installation and Debugging, Remarkable Pellet Quality

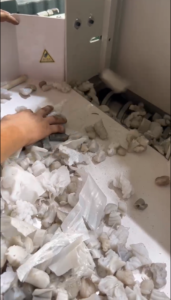

The installation work began, and our team, with its rich experience, completed all equipment connections and debugging in just half a day. When the machine started running, the client fed the plastic head material for a trial production run.

As the material smoothly passed through the low-temperature pelletizing process, one by one, glistening, plump, and transparent plastic pellets appeared. The client picked up the pellets, examined them carefully, and nodded in approval. The pellets’ luster, uniformity, and fullness far exceeded the client’s expectations.

The client said with genuine satisfaction, “This machine has completely solved my previous problems. Not only is the pellet quality excellent, but it also runs smoothly with low noise. It’s truly a good piece of equipment worth investing in!” Hearing this, I was genuinely relieved and happy.

3. The Advantages of the 150 Model Low-Temperature Recycling Pelletizer

Why are more and more plastic factory owners choosing this machine? The reason is simple: it truly achieves “high output, low energy consumption, and high quality.”

- High Output: The 150 model can achieve a stable output of 300 kilograms per hour, meeting the daily needs of medium to large factories.

- Low-Temperature Pelletizing: The air-cooled, low-temperature design prevents the material from secondary degradation under high-temperature conditions, resulting in better transparency and toughness for the pellets and ensuring stable quality.

- Energy-Saving and Eco-Friendly: Its low-energy operation saves on electricity costs compared to traditional equipment, helping factories reduce overall production expenses.

- Simple Operation: The intelligent design lowers the training costs for workers and reduces material waste caused by improper operation.

- Easy Maintenance: The reasonable structure makes it easy to disassemble and clean, saving maintenance time and improving production efficiency.

It is precisely because of these advantages that the 150 model low-temperature recycling pelletizer has gradually become an indispensable “capable assistant” in the plastics industry.

4. Customer Satisfaction is My Greatest Motivation

From initial communication to installation, and finally to the moment I saw the client’s satisfied smile, I deeply understood that a machine is not just cold steel; it carries a client’s hopes and trust.

Competition in the plastics industry is becoming increasingly fierce. Only by continuously innovating and optimizing can we stand out in the market. What we do is diligently manufacture every piece of equipment and earn our customers’ trust with service and quality.

5. Conclusion

Today’s visit and installation are just the beginning. In the future, we will continue to provide comprehensive after-sales service and technical support to our clients. Every word of affirmation from our customers is what drives us forward.

If you are looking for an efficient, energy-saving, and high-quality low-temperature plastic recycling pelletizer, the 150 model is definitely a choice worth owning. It can not only help you improve production efficiency but also bring tangible economic benefits to your business.

Customer satisfaction is our goal; customer success is our pride.

Friends in need are welcome to contact us. We will serve you with all our heart!