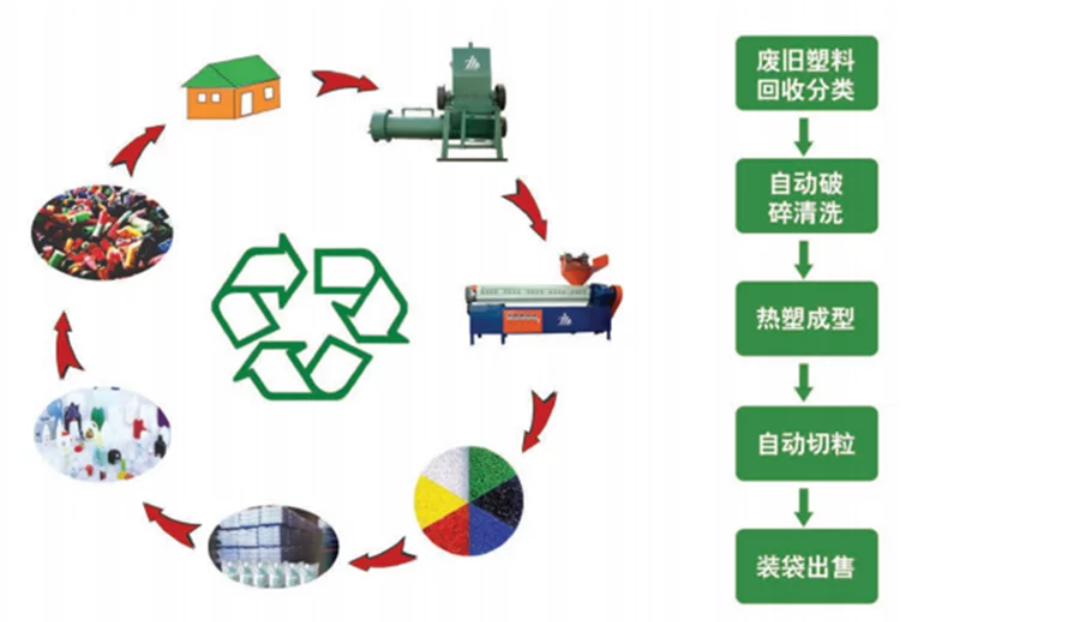

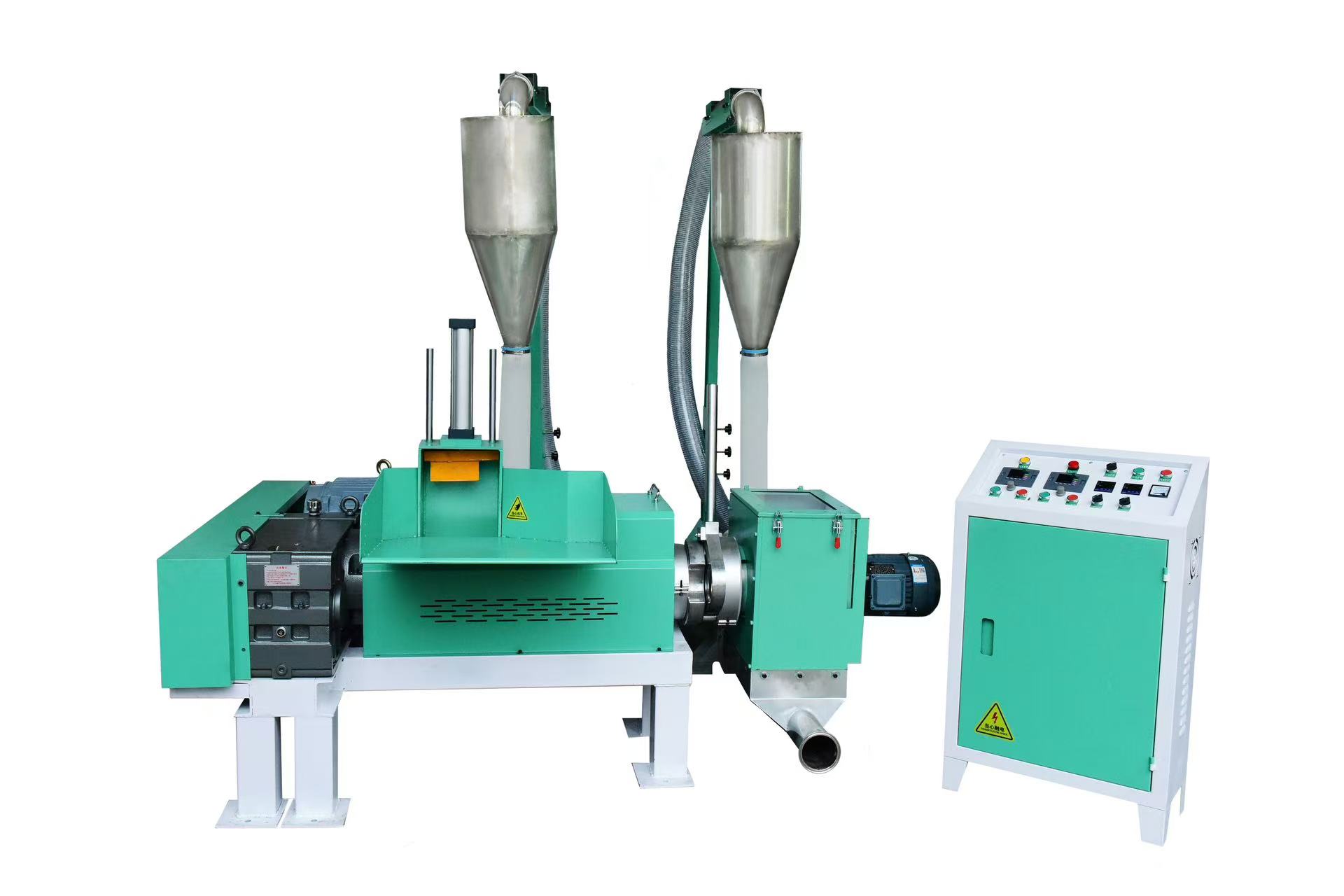

Plastic granulator application

The Air Plastic Recycler is used to recycle waste plastic materials. It is equipped with automatic thermostat and motorized filter change. It can also make pellets from the crushed material. Equipped with loading device, the cutter adopts speed-regulating motor, which can cut according to the feeding speed of the extruder. With high output, low noise,…

Read article