Customized Solutions · Precise Matching of Requirements

With the continuous growth in global plastic consumption, the recycling of plastic film materials has become a priority for environmental industries worldwide. Qatar’s client specifically required efficient regranulation of plastic film materials. After reviewing the provided material samples and thorough analysis, our technical team recommended and customized this YC-120 water-cooled granulator.

Compared to standard models, the YC-120 offers distinct advantages for processing lightweight, thin-film materials:

Smooth Feeding —— Film materials are lightweight, fluffy, and difficult to feed. This machine features an optimized feeding structure ensuring continuous, stable material entry into the screw.

High-Efficiency Extrusion —— The specially designed screw incorporates modifications tailored to film characteristics, enhancing plasticization and mixing efficiency.

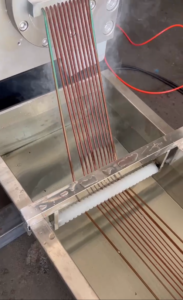

Rapid Cooling & Forming — The water-cooled strand pelletizing system rapidly cools pellets in minimal time, maintaining plump, uniform pellets.

Optimized Energy Consumption — While maintaining production capacity, the equipment minimizes unnecessary energy expenditure, aligning with international trends in energy conservation and environmental protection.

This machine not only meets the customer’s production capacity requirements (consistently producing 200-250 kg per hour) but also achieves high-quality pellets characterized by glossiness, uniformity, and porosity-free properties, ready for direct use in subsequent product processing.

II. Rigorous Testing · Quality is the Foundation of Trust

Today’s trial run serves as a comprehensive assessment of equipment quality. We selected plastic film matching the customer’s raw material for testing. The entire process—from startup, heating, feeding, and melt extrusion to water-cooled stranding, pelletizing, drying, and material collection—proceeded smoothly and efficiently.

The final pellets exhibited:

Regular shape and consistent size;

Vibrant color and smooth surface;

High strength with minimal breakage;

Stable output with negligible powder impurities.

Engineers on-site meticulously recorded parameters while repeatedly verifying pellet performance metrics, ensuring optimal equipment condition prior to delivery. This dedication to precision reflects not only our commitment to clients but also the craftsmanship ethos our brand has upheld for years.

III. Crossing Mountains and Seas: Chinese Manufacturing Reaches Qatar

Following successful trial runs, this YC-120 water-cooled pelletizer will be disassembled, packaged, loaded into containers, and shipped across thousands of miles to arrive at the client’s factory in Qatar.

As a key nation in the Middle East, Qatar has actively promoted sustainable development strategies in recent years, driving increasing demand for environmental protection industries and plastic recycling equipment. Our equipment entering this market reflects both the client’s recognition of Chinese manufacturing and their trust in our product quality and service.

Notably, the YC-120 is more than just a machine—it serves as a bridge for Sino-Qatari cooperation. It will empower our client to achieve resource recycling goals, revitalizing waste film into reusable plastic pellets and advancing the green development of Qatar’s plastics industry.

IV. Dedicated Service · Beyond Delivery

The shipment of equipment does not mark the end of our service. Rather, it signifies the beginning of our partnership. We commit to:

Remote Technical Support — Should customers encounter operational issues during use, our engineers provide online remote guidance;

Spare Parts Supply Assurance — We promptly provide wear parts and spare components to ensure long-term stable operation;

Continuous Optimization and Upgrades — We continually refine equipment performance based on customer feedback, keeping machines at the forefront of the industry.

We firmly believe that a machine’s true value lies not only in its production capacity and efficiency, but also in the peace of mind, confidence, and reassurance it provides customers throughout its use.

V. Looking Ahead · Co-Creating a New Chapter in Sustainability

Today, a YC-120 water-cooled pelletizer, embodying our sincerity and quality, embarks on its journey to Qatar. Tomorrow, more Chinese-made products will continue to reach the global market, serving customers across more countries and regions.

Amidst the global wave of environmental protection and circular economy, we stand ready to join hands with every partner to explore new frontiers in the plastic recycling industry. For we firmly believe:

One machine can transform an entire production line;

One partnership can propel an entire industry forward.