哪些类型的塑料适合造粒?塑料造粒材料选择和工艺综合指南

在回收制造行业中,塑料造粒是连接塑料废弃物与回收再利用的核心环节。通过特定的工艺,塑料造粒将废旧塑料或原生塑料原料转化为大小均匀、形状规则的颗粒。这些颗粒不仅便于储存和运输,还可以直接作为注塑、挤出、吹塑等下游加工的原料,实现塑料资源的循环利用。然而,并非所有塑料都能高效地进行造粒,聚合物类型、熔点特性、污染程度等因素直接决定了塑料是否适合进行造粒。识别哪些塑料适合进行造粒,对于企业提高生产效率、保证颗粒质量至关重要。

1. 首先了解塑料造粒工艺:热塑性塑料是核心适用材料

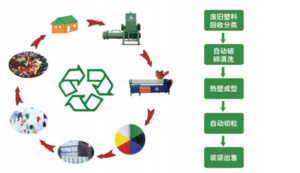

要判断一种塑料是否适合造粒,首先需要了解造粒的核心工艺。塑料造粒本质上是一个“熔融-成型-切割”的循环过程。它包括将塑料材料加热熔融,通过挤出设备将其成型为连续的线材,然后进行切割、冷却和干燥,最终形成可重复使用的颗粒。该工艺的关键要求是“塑料可反复熔融和成型”。因此,热塑性塑料成为造粒的主要候选材料。这些塑料在加热时可以软化熔融,在冷却时固化成型,并且其性能在反复加热后不会显著下降,完美契合造粒工艺的核心需求。

完整的塑料造粒过程通常包括6个关键步骤:

1. 分类和分级:根据树脂类型(例如 PET、HDPE)和质量等级分离塑料,以防止不同材料混合并影响颗粒质量。

2、清洁处理:除去塑料表面的污垢、标签黏合剂、金属杂质等污染物,防止杂质在熔融过程中破坏聚合物结构。

3、切碎预处理:将大块塑料或薄膜状物料切碎,减小其体积,保证后续熔融时加热均匀,进料顺畅。

4、熔融挤出:将预处理好的塑料送入挤出机,在设定的温度下加热熔融,然后通过模头挤出,形成连续的塑料线材。

5.切成颗粒:利用切粒机的刀片将挤出的线材切成固定长度的圆柱形或球形颗粒。

6. Cooling and Drying: Cool and solidify the pellets through water cooling or air cooling, then remove surface moisture to prevent mold growth or caking during storage.

2. Common Thermoplastics: Mainstream Choices and Characteristics for Pelletization

Among thermoplastics, 6 types of materials have become the “main force” in industrial pelletization due to their wide sources, low processing difficulty, and high recycling value. Their application scenarios, pelletization advantages, and precautions vary:

1. Polyethylene Terephthalate (PET)

• Common Uses: Beverage bottles (e.g., mineral water bottles), food storage containers, polyester synthetic fibers, cosmetic bottles.

• Pelletization Advantages: It has a moderate melting point (about 260°C), requiring low energy consumption during heating and offering high processing efficiency. Recycled PET pellets have a wide range of uses and can be directly used in the production of polyester fabrics, carpet fibers, packaging films, etc., with stable market demand.

• Precautions: PET is highly absorbent of moisture in the air. If it is not thoroughly dried before pelletization, a “hydrolysis reaction” will occur during melting, leading to the breakage of polymer chains and a significant decrease in pellet strength. Therefore, moisture must be removed in advance using a dryer.

2. High – Density Polyethylene (HDPE)

• Common Uses: Milk jugs, detergent bottles, municipal pipelines, plastic turnover boxes, trash cans.

• Pelletization Advantages: It has a tough texture, is resistant to acid and alkali corrosion, is not easy to degrade during melting, and has little performance loss during the pelletization process. Recycled HDPE pellets can be directly used to manufacture new plastic bottles, pipelines, or “plastic wood” (for outdoor flooring), with multiple applicable scenarios.

• Precautions: The color of HDPE has a great impact on recycling applications. For example, black HDPE pellets are difficult to dye into light colors. Therefore, HDPE must be sorted by color (e.g., white, transparent, black) before pelletization to avoid limiting application scenarios after mixing.

3. Low – Density Polyethylene (LDPE)

• Common Uses: Supermarket shopping bags, food cling film, agricultural films, extruded plastic bottles (e.g., small shampoo sample bottles).

• Pelletization Advantages: It has a soft texture and low density, with a relatively low melting temperature (about 110 – 130°C) and low processing difficulty. It can convert a large amount of post – consumer film waste into usable pellets, solving the problem of difficult recycling of film – like waste. Recycled pellets can be used to make new films or small molded parts (e.g., plastic bottle caps).

• Precautions: LDPE films have a large volume and low density, which will lead to uneven feeding if directly fed into the extruder. Therefore, LDPE films must be compressed to reduce volume using a compactor before pelletization to improve feeding efficiency.

4. Polypropylene (PP)

• Common Uses: Food containers (e.g., take – out lunch boxes), plastic bottle caps, automotive bumper parts, washing machine inner drums.

• Pelletization Advantages: It has strong chemical resistance (resistant to most acids and alkalis) and high temperature resistance (long – term use temperature is about 100°C), and maintains good performance after recycling. PP pellets are mainly used for injection molding and can produce new food containers and automotive interior parts, with high industrial application value.

• Precautions: The melting point of PP (about 160 – 170°C) is higher than that of PE (polyethylene). If the temperature is not properly controlled, local overheating and degradation are likely to occur. Therefore, the temperature of the extruder must be accurately controlled during pelletization to avoid discoloration or performance degradation of the pellets.

5. Polystyrene (PS)

• Common Uses: Disposable lunch boxes, CD/DVD cases, electrical enclosures (e.g., old TV casings), foam cushioning materials (EPS).

• Pelletization Advantages: Rigid PS has a stable texture, and can be reused to manufacture similar rigid products after pelletization. Expanded polystyrene (EPS, i.e., “foam plastic”), although having a large volume, can also be pelletized after pre – compaction, realizing the recycling of foam waste.

• Precautions: The volume of EPS is dozens of times that of rigid PS of the same weight. EPS must be compacted into blocks using special equipment before pelletization; otherwise, efficient melting cannot be achieved, and equipment space will be wasted.

6. Polycarbonate (PC)

• Common Uses: Safety goggles, water dispenser buckets, laptop casings, baby bottles (PC that meets safety standards).

• Pelletization Advantages: It has high transparency and strong impact resistance. Recycled PC pellets can be used to manufacture products requiring strength and transparency (e.g., lamp housings, safety barriers), with great potential for high – value utilization.

• Precautions: PC is extremely sensitive to temperature. If the heating temperature is too high (exceeding 300°C), the material will turn yellow and degrade. Therefore, the extrusion temperature must be strictly controlled during pelletization, and repeated heating should be avoided to reduce performance loss.

3. Engineering Thermoplastics: Pelletization Choices for High – Requirement Scenarios

In addition to the above – mentioned general plastics, some “engineering thermoplastics” can also be recycled through pelletization due to their special properties (e.g., high strength, high temperature resistance). They are mainly used in high – end industrial scenarios but have higher processing requirements:

• Acrylonitrile – Butadiene – Styrene Copolymer (ABS): Commonly used in automotive interior parts (e.g., instrument panels), electronic product enclosures (e.g., router casings), and Lego toys. The advantage of ABS pellets is the balance between toughness and rigidity, making them suitable for injection molding. After recycling, they can be used to manufacture mid – to low – end automotive parts or toys.

• Nylon (Polyamide, PA): Mostly used in industrial gears, bearings, textile fabrics (nylon cloth), and mountaineering ropes. Nylon pellets are wear – resistant and tensile. After recycling, they are mainly used to produce industrial accessories. They must be thoroughly dried before pelletization to avoid hydrolysis.

• Polyoxymethylene (POM): Often used in precision mechanical parts (e.g., zipper sliders, printer gears). The pelletization of POM requires strict temperature control to prevent the production of harmful gases due to high – temperature degradation. Recycled pellets are mainly used in low – precision engineering parts.

• Thermoplastic Polyurethane (TPU): Suitable for making sports shoe soles, cable sheaths, and mobile phone cases. The advantage of TPU is its flexibility and wear resistance. During pelletization, the mixing of impurities must be avoided; otherwise, its elasticity will be affected. Recycled pellets can be used to manufacture low – end TPU products.

The pelletization threshold for such engineering plastics is relatively high. It is necessary to adjust parameters such as temperature and rotation speed according to the characteristics of each material, and most of them adopt “pure material pelletization” (without mixing other plastics) to ensure the performance of recycled pellets.

4. Which Plastics Are Not Suitable for Traditional Pelletization?

Not all plastics can be recycled through traditional pelletization processes. The following 3 types of plastics require special attention:

• Thermosetting Plastics: Such as Bakelite (used in old socket casings), epoxy resin (used in circuit board packaging), and melamine (used in melamine tableware). Once these plastics are cured, they cannot be melted when heated and can only be crushed for use as fillers, not made into pellets.

• Highly Contaminated or Mixed Plastics: If a large amount of metal, rubber, or paint is mixed into the plastic, or different types of plastics (e.g., PET and PE) are not separated, “layer separation” or “impurity spots” will occur during melting, resulting in poor pellet strength and unqualified appearance, making them unusable.

• Biodegradable Plastics (e.g., PLA): Although PLA is a thermoplastic and can be melted for pelletization, the traditional pelletization process may damage its biodegradability. Special equipment is required to control the temperature and processing environment to maintain its degradation characteristics, so it is not suitable for conventional pelletization lines.

5. Five Key Factors Affecting the Suitability of Plastic Pelletization

To determine whether a type of plastic is suitable for pelletization, we cannot only consider its type but also comprehensively evaluate the following 5 aspects:

1. Melting Point Compatibility: The melting point of the plastic must be compatible with the temperature range of the pelletization equipment (most equipment can handle plastics with a melting point of 100 – 300°C). If the melting point is too high (e.g., some special plastics exceed 400°C), the existing equipment cannot heat and melt them, making them unsuitable for pelletization.

2. Contamination Level: Impurities on the plastic surface (e.g., oil stains, metals, paper) will directly affect the pellet quality. Plastics that are severely contaminated and difficult to clean (e.g., plastics stained with asphalt) have high pelletization costs and low profits, so pelletization is not recommended.

3. Moisture Sensitivity: “Hygroscopic plastics” such as PET, nylon, and PC will cause bubbles and cracks in the pellets if they are pelletized without drying. Therefore, they need to be dried in advance. If an enterprise does not have drying equipment, it is necessary to carefully select such plastics.

4. Color and Appearance: Dark – colored plastics (e.g., black, dark brown) are difficult to dye, and recycled pellets can only be used to manufacture products of the same color system, with limited application scenarios. Transparent or light – colored plastics have higher recycling value and better compatibility.

5. Degradation Resistance: Some plastics (e.g., PVC) are prone to release harmful gases after repeated heating, and their performance degrades rapidly. Even if they can be pelletized, the strength and safety of the recycled pellets are difficult to meet the standards, resulting in high long – term use costs.

6. Plastic Pellets After Pelletization: Wide Application Scenarios

Plastic pellets made through pelletization can cover multiple industries depending on the type of raw materials:

• Packaging Industry: PET and HDPE pellets are used to manufacture beverage bottles and food cans; LDPE pellets are used to produce cling film and express packaging bags.

• Automotive Industry: ABS and PP pellets are used to make instrument panels and bumpers; PA pellets are used to produce automotive bearings and oil pipes.

• Construction Industry: HDPE pellets are used to manufacture municipal pipelines; PP pellets are used to produce plastic flooring and insulation boards.

• Textile Industry: PET pellets can be melted and spun into polyester fibers, which are used to make clothing, carpets, and curtains.

• Consumer Goods Industry: PS and PP pellets are used to manufacture toys, plastic basins, and trash cans; TPU pellets are used to make shoe materials and mobile phone cases.

通过塑料造粒,将原本需要填埋或焚烧的塑料废弃物转化为标准化的工业原料,不仅减少了资源浪费,也为企业节省了购买原生塑料的成本,是推动塑料循环经济的关键环节。

如果您需要塑料造粒机,请联系我。